Denye aha na mgbasa ozi mmekọrịta anyị maka ozi ozugbo

Laser Wave Na-aga n'ihu

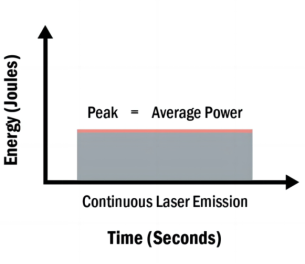

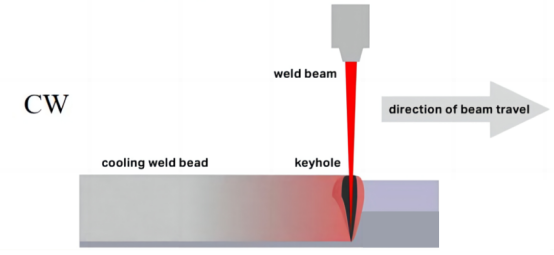

CW, okwu a na-akpọ "Continuous Wave," na-ezo aka na sistemụ laser nwere ike inye mmepụta laser na-enweghị nkwụsị n'oge ọrụ. N'ịbụ nke a maara site n'ike ha na-ewepụta laser mgbe niile ruo mgbe ọrụ ahụ kwụsịrị, a na-amata laser CW site na ike kachasị elu ha na ike dị elu karịa ụdị laser ndị ọzọ.

Ngwa dị iche iche

N'ihi njirimara mmepụta ha na-aga n'ihu, laser CW na-achọta ọtụtụ ojiji n'ọhịa dịka ịkpụ ígwè na ịgbado ọla kọpa na aluminom, na-eme ka ha bụrụ otu n'ime ụdị laser ndị a na-ejikarị eme ihe na nke a na-ejikarị eme ihe. Ike ha nwere inye ike na-aga n'ihu na nke na-agbanwe agbanwe na-eme ka ha baa uru ma n'ihe gbasara nhazi ziri ezi na ọnọdụ mmepụta oke.

Usoro Nhazi Usoro

Ịgbanwe laser CW maka arụmọrụ usoro kacha mma gụnyere ilekwasị anya na ọtụtụ paramita dị mkpa, gụnyere nhazi ike, ọnụọgụ defocus, dayameta ntụpọ beam, na ọsọ nhazi. Nhazi ziri ezi nke paramita ndị a dị oke mkpa iji nweta nsonaazụ nhazi kacha mma, hụ na arụmọrụ na ịdị mma na ọrụ igwe laser.

Ihe osise ike laser na-aga n'ihu

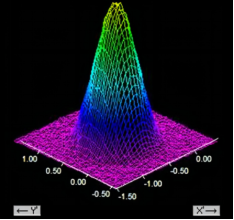

Àgwà nkesa ike

Otu ihe pụrụ iche nke laser CW bụ nkesa ike Gaussian ha, ebe nkesa ike nke akụkụ obe nke laser na-ebelata site na etiti gaa n'ihu na usoro nkesa Gaussian (nkesa nkịtị). Njirimara nkesa a na-enye laser CW ohere inweta nkenke nlebara anya dị elu na arụmọrụ nhazi, ọkachasị na ngwa chọrọ ntinye ike siri ike.

Ihe osise nkesa ike laser CW

Uru nke Ịgbado Ọkụ Laser Na-aga n'ihu (CW)

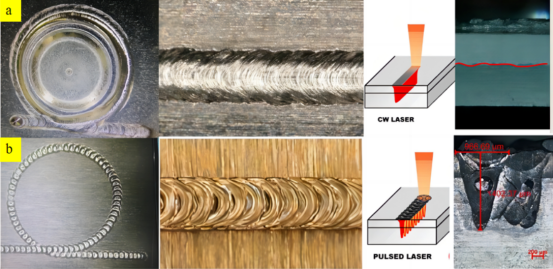

Echiche Microstructural

Inyocha obere nhazi nke ígwè na-egosi uru dị iche iche nke ịgbado ọkụ laser Continuous Wave (CW) karịa ịgbado ọkụ pulse Quasi-Continuous Wave (QCW). Ịgbado ọkụ pulse QCW, nke oke ugboro ole ya na-egbochi, nke na-adịkarị ihe dị ka 500Hz, na-eche mgbanwe n'etiti ọnụego mgbada na omimi ịbanye. Oke ọsọ mgbada na-ebute omimi zuru oke, ebe oke ọsọ mgbada na-egbochi ọsọ ịgbado ọkụ, na-ebelata arụmọrụ. N'ụzọ dị iche, ịgbado ọkụ laser CW, site na nhọrọ nke dayameta isi laser kwesịrị ekwesị na isi ịgbado ọkụ, na-enweta ịgbado ọkụ dị irè ma na-aga n'ihu. Usoro a na-egosi na ọ bụ ihe a pụrụ ịtụkwasị obi karịsịa na ngwa ndị chọrọ iguzosi ike n'ezi ihe mkpuchi dị elu.

Ntụle Mmetụta Okpomọkụ

Site n'echiche nke mmetụta okpomọkụ, njikọta laser QCW pulse na-enwe nsogbu nke njikọta, nke na-eduga na ikpo ọkụ ugboro ugboro nke njikọta weld. Nke a nwere ike iweta enweghị nkwekọrịta n'etiti obere nhazi nke ígwè ahụ na ihe nne na nna ya, gụnyere mgbanwe na nha mwepụ na ọnụego oyi, si otú a na-amụba ohere nke mgbawa. N'aka nke ọzọ, njikọta laser CW na-ezere nsogbu a site n'inye usoro ikpo ọkụ yiri nke ahụ na nke na-aga n'ihu.

Mfe nke Mgbanwe

Maka ọrụ na mgbanwe, ịgbado ọkụ laser QCW chọrọ nhazi nke ọma nke ọtụtụ paramita, gụnyere ugboro ugboro ugboro ugboro, ike kachasị elu, obosara mkpali, okirikiri ọrụ, na ihe ndị ọzọ. Ịgbado ọkụ laser CW na-eme ka usoro mgbanwe dị mfe, na-elekwasị anya karịsịa na ụdị ebili mmiri, ọsọ, ike, na oke nkwụsị, na-eme ka nsogbu ọrụ dịkwuo mfe.

Ọganihu Teknụzụ na CW Laser Welding

Ọ bụ ezie na a maara ịgbado ọkụ laser QCW maka ike dị elu ya na obere ntinye okpomọkụ, ọ bara uru maka ihe ndị na-emetụta okpomọkụ na ihe ndị dị gịrịgịrị nke ukwuu, ọganihu na teknụzụ ịgbado ọkụ laser CW, karịsịa maka ngwa ike dị elu (karịsịa karịa watts 500) na ịgbado ọkụ miri emi dabere na mmetụta oghere igodo, emeela ka oke ngwa ya na arụmọrụ ya dịkwuo elu. Ụdị laser a dabara adaba karịsịa maka ihe ndị dị arọ karịa 1mm, na-enweta oke akụkụ dị elu (karịa 8:1) n'agbanyeghị ntinye ọkụ dị elu.

Ịgbado ọkụ laser nke a na-akpọ Quasi-Continuous Wave (QCW)

Nkesa Ike Elekwasịrị Anya

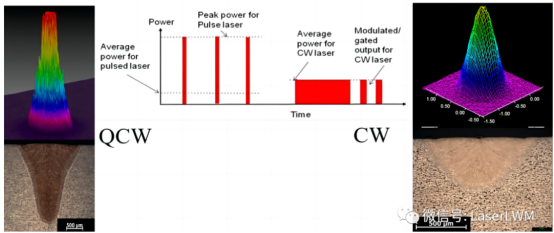

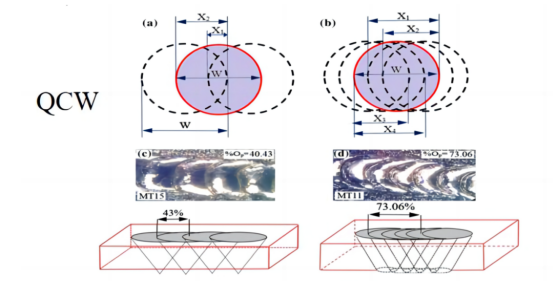

QCW, nke pụtara "Quasi-Continuous Wave," na-anọchite anya teknụzụ laser ebe laser na-ewepụta ìhè n'ụzọ na-aga n'ihu, dịka egosiri na eserese a. N'adịghị ka nkesa ike otu nke laser na-aga n'ihu otu ụdị, laser QCW na-etinye ike ha nke ọma. Njirimara a na-enye laser QCW njupụta ike dị elu, na-agbanwe ka ọ bụrụ ikike ịbanye n'ime ahụ siri ike. Mmetụta metallurgical sitere na ya yiri ọdịdị "mbọ" nwere oke omimi-ruo-obosara dị mkpa, na-enye laser QCW ohere ịka mma na ngwa ndị metụtara alloys na-egosipụta ike dị elu, ihe ndị na-emetụta okpomọkụ, na obere-welding nkenke.

Mbelata Nkwụsi Ike na Mbelata Ntụnye Aka Plume

Otu n'ime uru pụtara ìhè nke ịgbado ọkụ laser QCW bụ ikike ya ibelata mmetụta nke plọm ígwè na ọnụego nnabata ihe ahụ, na-eduga na usoro kwụsiri ike karị. N'oge mmekọrịta laser na ihe, mmịpụta siri ike nwere ike ịmepụta ngwakọta nke uzuoku ígwè na plasma n'elu ọdọ mmiri agbaze, nke a na-akpọkarị plọm ígwè. Plọm a nwere ike ichebe elu ihe ahụ site na laser, na-akpata nnyefe ike na-adịghị akwụsi ike na ntụpọ dị ka spatter, ebe mgbawa, na olulu. Agbanyeghị, mwepụ nke laser QCW na-apụta n'oge (dịka ọmụmaatụ, mgbawa 5ms na-esote nkwụsịtụ 10ms) na-eme ka mkpali laser ọ bụla rute n'elu ihe ahụ na-enweghị mmetụta nke plọm ígwè, na-ebute usoro ịgbado ọkụ kwụsiri ike, nke bara uru karịsịa maka ịgbado ọkụ mpempe akwụkwọ dị gịrịgịrị.

Stable Melt Pool Dynamics

Mmetụta nke ọdọ mmiri ịgbaze, karịsịa n'ihe gbasara ike ndị na-arụ ọrụ na oghere igodo, dị oke mkpa n'ịchọpụta ụdị ịgbaze ahụ. Laser ndị na-aga n'ihu, n'ihi na ha na-adịte aka na mpaghara okpomọkụ buru ibu, na-emepụta ọdọ mmiri ịgbaze buru ibu nke jupụtara na ígwè mmiri mmiri. Nke a nwere ike ibute ntụpọ metụtara ọdọ mmiri ịgbaze buru ibu, dị ka ọdịda oghere igodo. N'ụzọ dị iche, ike lekwasịrị anya na obere oge mmekọrịta nke ịgbaze laser QCW na-etinye ọdọ mmiri ịgbaze gburugburu oghere igodo ahụ, na-ebute nkesa ike dị otu na obere ohere nke porosity, mgbawa, na mgbawa.

Mpaghara Mbelata nke Okpomọkụ (HAZ)

Ihe ndị na-agbado ọkụ laser na-aga n'ihu na-eme ka ihe ndị a na-eme ka okpomọkụ na-aga n'ihu, na-eduga n'itinye okpomọkụ dị ukwuu n'ime ihe ahụ. Nke a nwere ike ibute mgbanwe okpomọkụ na-adịghị mma na ntụpọ nrụgide na-akpata na ihe ndị dị gịrịgịrị. Laser QCW, site na ọrụ ha na-aga n'ihu, na-enye ohere ka ihe ndị ahụ jụọ oyi, si otú a na-ebelata mpaghara okpomọkụ na ntinye okpomọkụ. Nke a na-eme ka njikọta laser QCW dabara adaba karịsịa maka ihe dị gịrịgịrị na ndị dị nso na ihe ndị na-adịghị emetụta okpomọkụ.

Ike Elu Elu

N'agbanyeghị na ha nwere otu ike nkezi dịka laser na-aga n'ihu, laser QCW na-enweta ike kachasị elu na njupụta ike, na-ebute ịbanye n'ime miri emi na ikike ịgbado ọkụ siri ike. Uru a pụtara ìhè karịsịa na ịgbado ọkụ nke mpempe akwụkwọ dị gịrịgịrị nke ọla kọpa na aluminom alloys. N'ụzọ dị iche, laser na-aga n'ihu nwere otu ike nkezi nwere ike ọ gaghị eme akara n'elu ihe ahụ n'ihi obere njupụta ike, na-eduga na ntụgharị uche. Laser ndị na-aga n'ihu dị elu, ọ bụ ezie na ha nwere ike ịgbaze ihe ahụ, nwere ike ịnweta mmụba dị nkọ na ọnụego nnabata mgbe agbazechara, na-akpata omimi agbaze a na-achịkwaghị achịkwa na ntinye okpomọkụ, nke na-adịghị mma maka ịgbado ọkụ mpempe akwụkwọ dị gịrịgịrị ma nwee ike ibute enweghị akara ma ọ bụ ọkụ, na-emezughị ihe achọrọ maka usoro.

Ntụnyere nsonaazụ ịgbado ọkụ n'etiti laser CW na QCW

a. Laser Ebili Na-aga n'ihu (CW):

- Ọdịdị nke ntu e ji laser mechie

- Ọdịdị nke njikọta njikọta kwụ ọtọ

- Ihe osise eserese nke mwepụta laser

- Ngafe nke ogologo oge

b. Laser nke na-aga n'ihu (QCW):

- Ọdịdị nke ntu e ji laser mechie

- Ọdịdị nke njikọta njikọta kwụ ọtọ

- Ihe osise eserese nke mwepụta laser

- Ngafe nke ogologo oge

- * Isi mmalite: Edemede nke Willdong dere, site na WeChat Public Account LaserLWM.

- * Njikọ akụkọ mbụ: https://mp.weixin.qq.com/s/8uCC5jARz3dcgP4zusu-FA.

- Ihe dị n'isiokwu a bụ maka mmụta na nkwukọrịta naanị, ikike nwebisiinka niile bụkwa nke onye dere ya. Ọ bụrụ na mmebi iwu nwebisiinka metụtara ya, biko kpọtụrụ anyị ka anyị wepụ ya.

Oge ozi: Maachị-05-2024